Piocol-601 Surface Repair Putty

Piocol-601 Surface Repair Putty is a two-part polymer system with heat resistance up to 220°C. It is an excellent solution for rectifying surface imperfections in sheet metals as well as castings. Piocol-601 is easy to mix and forms a creamy paste which can be applied by a putty blade to the cleaned and degreased surface.

Features

High Heat Resistance: Withstands temperatures up to 220°C.Excellent Adhesion: Bonds well with all metals and nonmetals.

Mechanical Strength: Piocol-601 has excellent mechanical properties and can be sanded or machined after curing.

Chemical Resistance: Stands up to various chemicals after curing.

High Electrostatic Conductivity: Suitable for electrostatic coating applications.

Flow Resistance: Non-sag.

No cracks, bubbles or color variation during oven curing process in powder coating applications.

Optimal solutions for Powder Coating Applications.

Typical Applications

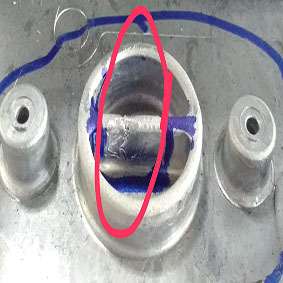

Sealing porosity and pinholes in castings for powder coating applications.

Repairing minor and major surface defects in fine sheet metal fabrications.

Masking grind marks due to its exceptional adhesion.

Porosity filling in metal castings.

Heat-resistant applications up to 220°C without time bound.

Powder coating applications.

Use as temperature-resistant adhesive with high-bonding strength.

Technical Specifications

Components: 2

Viscosity: 80,000 CPS

Hardness: 60 Shore D

Tensile Strength: 8000 psi

Heat Resistance: 220°C

Thermal Conductivity: 15 BTU

Shrinkage: 0.1% Max

Elongation: 1.2% Max

Thermal Expansion: 4.1 x 10^-5

How to Use

Preparation: Clean and degrease the surface thoroughly.

Mixing: Combine Part A and Part B as per the pre-measured kit instructions.

Application: Apply the mixed putty to the prepared surface using a putty blade.

Curing Time: 18 Hours.

Heat Curing: Cure at 120°C in oven for 1 hour.

Finishing: Once cured, the putty can be sanded or machined as required.

Industrial Applications:

- Automotive Industry (up to 220°C):

Sealing porosities in engine blocks.

Repairing minor surface defects on car body panels.

Fixing grind marks on vehicle parts.

- Manufacturing and Fabrication (up to 220°C):

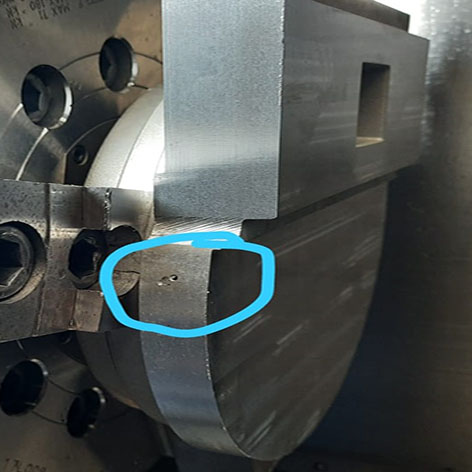

Smoothing out surface imperfections in machined components.

Repairing defects in sheet metal parts.

Filling pinholes in metal castings.

Creating a smooth, defect-free surface for powder coating.

- Electronics and Electrical Industry (up to 220°C):

Improving surface finish of metal heat sinks.

Fixing defects in metal enclosures.

Repairing surface imperfections in electrical components.

- Foundry and Casting (up to 220°C):

Sealing porosities in cast metal parts.

Repairing defects in casting molds.

Filling pinholes in metal castings.

- Oil and Gas Industry (up to 220°C):

Fixing surface defects in metal pipelines.

Repairing minor defects in valve bodies.

Sealing porosities in high-temperature pipes.

- HVAC and Refrigeration (up to 220°C):

Repairing surface defects in heat exchangers.

Sealing porosities in compressor housings.

Fixing minor defects in HVAC components.

- Construction and Infrastructure (up to 220°C):

Repairing surface imperfections in structural steel components.

Fixing grind marks on metal parts.

Sealing porosities in high-temperature metal structures.

- Marine Industry (up to 220°C):

Repairing surface defects in boat hulls.

Sealing porosities in marine engine parts.

Fixing minor defects in metal components.

- Aerospace Industry (up to 220°C):

Sealing porosities in aircraft engine components.

Repairing minor surface defects in turbine blades.

Fixing grind marks on aerospace parts.

- Power Generation (up to 220°C):

Repairing surface defects in turbine components.

Sealing porosities in steam pipes.

Fixing minor defects in power plant equipment.

- Heavy Machinery (up to 220°C):

Smoothing out surface imperfections in bearings.

Repairing defects in housings and linings.

Sealing porosities in industrial machinery components.

- Railway Industry (up to 220°C):

Repairing surface defects in train components.

Sealing porosities in high-temperature parts.

Fixing minor defects in railway equipment.

- Chemical Processing (up to 220°C):

Repairing surface defects in chemical reactors.

Sealing porosities in high-temperature tanks.

Fixing minor defects in process piping.

- Mining Industry (up to 220°C):

Repairing surface defects in conveyor components.

Sealing porosities in high-temperature mining equipment.

Fixing minor defects in metal parts.

- Textile Industry (up to 220°C):

Repairing surface defects in dyeing machines.

Sealing porosities in high-temperature textile machinery.

Fixing minor defects in metal components.

- Food and Beverage Industry (up to 220°C):

Repairing surface defects in cooking equipment.

Sealing porosities in high-temperature processing machinery.

Fixing minor defects in metal parts.

- Pharmaceutical Industry (up to 220°C):

Repairing surface defects in sterilization equipment.

Sealing porosities in high-temperature reactors.

Fixing minor defects in processing machinery.

- Pulp and Paper Industry (up to 220°C):

Repairing surface defects in steam pipes.

Sealing porosities in high-temperature boilers.

Fixing minor defects in processing equipment.

- Plastics Industry (up to 220°C):

Repairing surface defects in extrusion equipment.

Sealing porosities in injection molding machines.

Fixing minor defects in high-temperature machinery.

- Printing Industry (up to 220°C):

Repairing surface defects in printing presses.

Sealing porosities in drying equipment.

Fixing minor defects in high-temperature components.

- Woodworking Industry (up to 220°C):

Repairing surface defects in kiln components.

Sealing porosities in high-temperature drying equipment.

Fixing minor defects in woodworking machinery.

- Ceramics Industry (up to 220°C):

Repairing surface defects in kilns.

Sealing porosities in high-temperature furnaces.

Fixing minor defects in ceramic processing equipment.

- Glass Industry (up to 220°C):

Repairing surface defects in glass melting furnaces.

Sealing porosities in forming equipment.

Fixing minor defects in high-temperature components.

- Laboratory Equipment (up to 220°C):

Repairing surface defects in test equipment.

Sealing porosities in high-temperature apparatus.

Fixing minor defects in laboratory components.

- Medical Equipment (up to 220°C):

Repairing surface defects in sterilization units.

Sealing porosities in high-temperature medical devices.

Fixing minor defects in metal components.

Contact Us

For more information, technical support, or to place an order, please contact our customer service team. We are here to help you achieve the best results with Piocol-601 Surface Repair Putty.